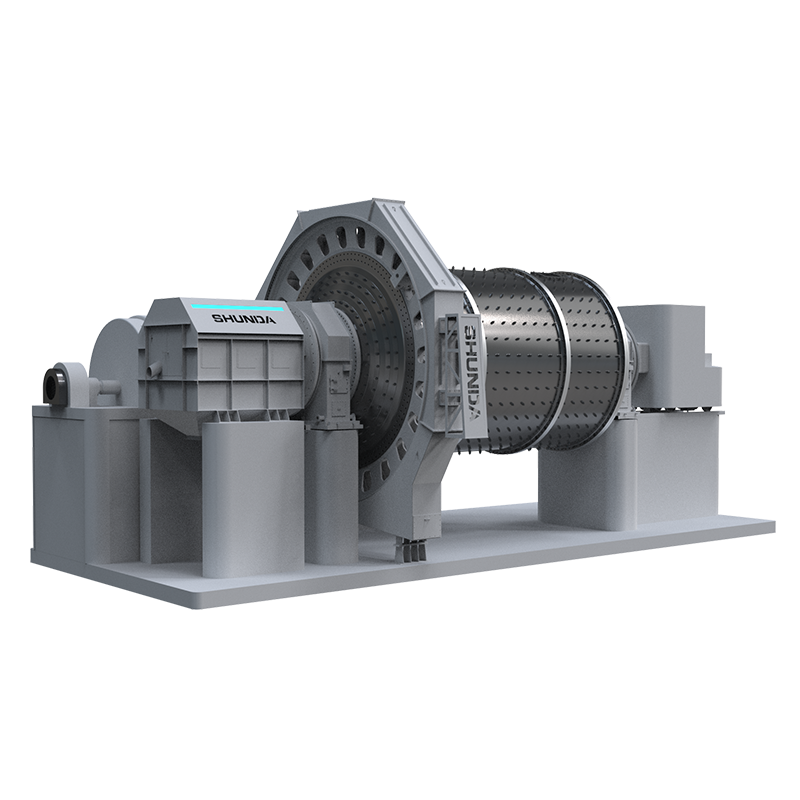

Recently, the full set of equipment and spare parts of the MQY4560 overflow ball mill customized by Shunda Heavy Mining Group for Russian customers have been successfully shipped, which will serve a lead and zinc mining project and help the high-quality development of the industry.

The rotary part of MQY series ball mill is composed of cast steel end cover and welded cylinder, and the whole frame is on the bearing part. At the same time, the ball mill is equipped with high pressure synchronous frequency conversion motor, which drives the pinion through the transmission coupling and the big gear installed on the rotary part to reduce the transmission and drive the cylinder to carry out the rotary movement. The high voltage synchronous variable frequency motor realizes soft start by frequency converter. The cylinder is equipped with a suitable grinding medium - steel balls. Under the action of centrifugal force and friction force, the grinding medium is raised to a certain height and falls in a throwing or draining state. The material to be ground is continuously entered into the cylinder by the feed port, crushed by the moving grinding medium, and the finished product is discharged out of the machine through the discharge port and the force of the continuous feed.

Cylinder diameter: 4.5m

Cylinder length: 6m

Installed power: 2500kW

Process features: Advanced overload protection, automatic monitoring and prediction of equipment failure capabilities. The built-in slag screen has the function of automatically removing large materials and broken steel balls to protect the next section of equipment.

MQY4560 adopts frequency conversion starting mode to reduce energy consumption while facilitating operation and extending service life. In order to meet the high standard requirements of export transportation, the equipment adopts a split cylinder mechanism, which is divided into 4 parts, which is larger and more difficult to process than the previous ball mill.

Loading site:

Ready to go: