Since the first set of semi-mobile rotary crushing stations with independent intellectual property rights independently developed by Shunda Mining Group was put into operation in June 2023, three sets of semi-mobile rotary crushing stations (ore crushing systems) have been put into operation successively. The various operation indicators of the crushing stations have met the design requirements and passed the user equipment acceptance. The fourth SMG5475 semi-mobile rotary crushing station (waste rock crushing system) was put into operation with materials on January 15, 2025.

Due to the stable operation and user recognition of the first three sets of semi-mobile rotary crushing stations, two more sets of waste rock SMG5475 semi-mobile rotary crushing stations were signed in May 2023. The successful operation of the fourth semi-mobile rotary crushing station marks that the semi-mobile rotary crushing station with independent intellectual property rights has gradually matured in terms of design, research and development, manufacturing and operation technology.

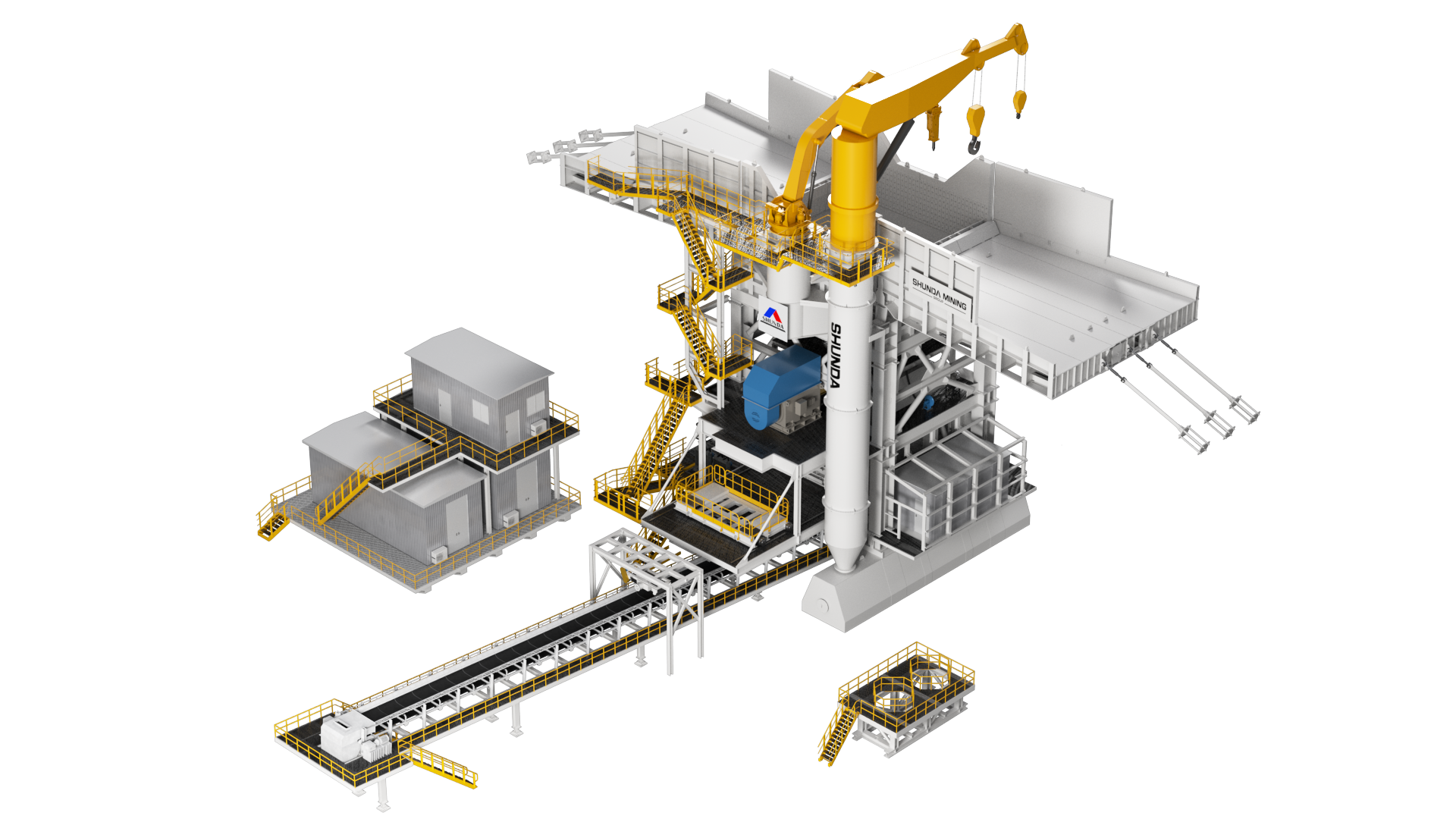

The SMG5475 semi-mobile gyratory crushing station for waste rock provided by Shunda Mining Group selects the SDG5475 gyratory crusher. The maximum feed particle size is ≤1200mm, the output particle size P80 is ≤250mm, and the maximum processing capacity is 3,500 tons per hour. The supply scope of the semi-mobile gyratory crushing station includes: Gyratory crushers, discharge belts, E-House, cantilever cranes, hydraulic hammers, dry mist dust suppression systems, bag dust removal systems, magnetic separators, metal detectors, belt scales, fire protection systems, etc.

In May 2024, the group held a field observation meeting for the semi-mobile rotary crushing station in Nanchang City, inviting experts and leaders in the industry to attend the site for on-site observation and technical exchanges. Experts unanimously agree that the successful operation of the domestic semi-mobile crushing station has broken the foreign technological monopoly, significantly reduced the investment cost of mines, and made innovations in the design of the semi-mobile crushing station.

The semi-mobile rotary crushing station designed and manufactured by Shunda Mining, based on the absorption of foreign technology, adopts a modular design, which reduces the relocation cost and changes the traditional overall relocation method, meeting the relocation requirements of semi-mobile rotary crushing stations in Chinese mines.

The successful operation of the semi-mobile rotary crushing station has also attracted a large number of foreign customers to visit and inspect the site. Its design structure and operation indicators have been recognized by foreign customers, and in 2024, the semi-mobile rotary crushing station was successfully launched to the international market.

Foreign customers

Communication

In November 2024, Shunda Mining Group signed a contract with the KGOK project in Russia for two sets of semi-mobile rotary crushing stations SMG6089 for iron ore ore discharge, with a maximum processing capacity of 5,500 tons per hour. The delivery date is May 2025. The signing of this semi-mobile rotary crushing station marks a leap for China's mining crushing equipment from introduction, digestion to entering the international market!