- Home

- >

- Products

- >

- Grinding Equipment

- >

- Ball Mill

- >

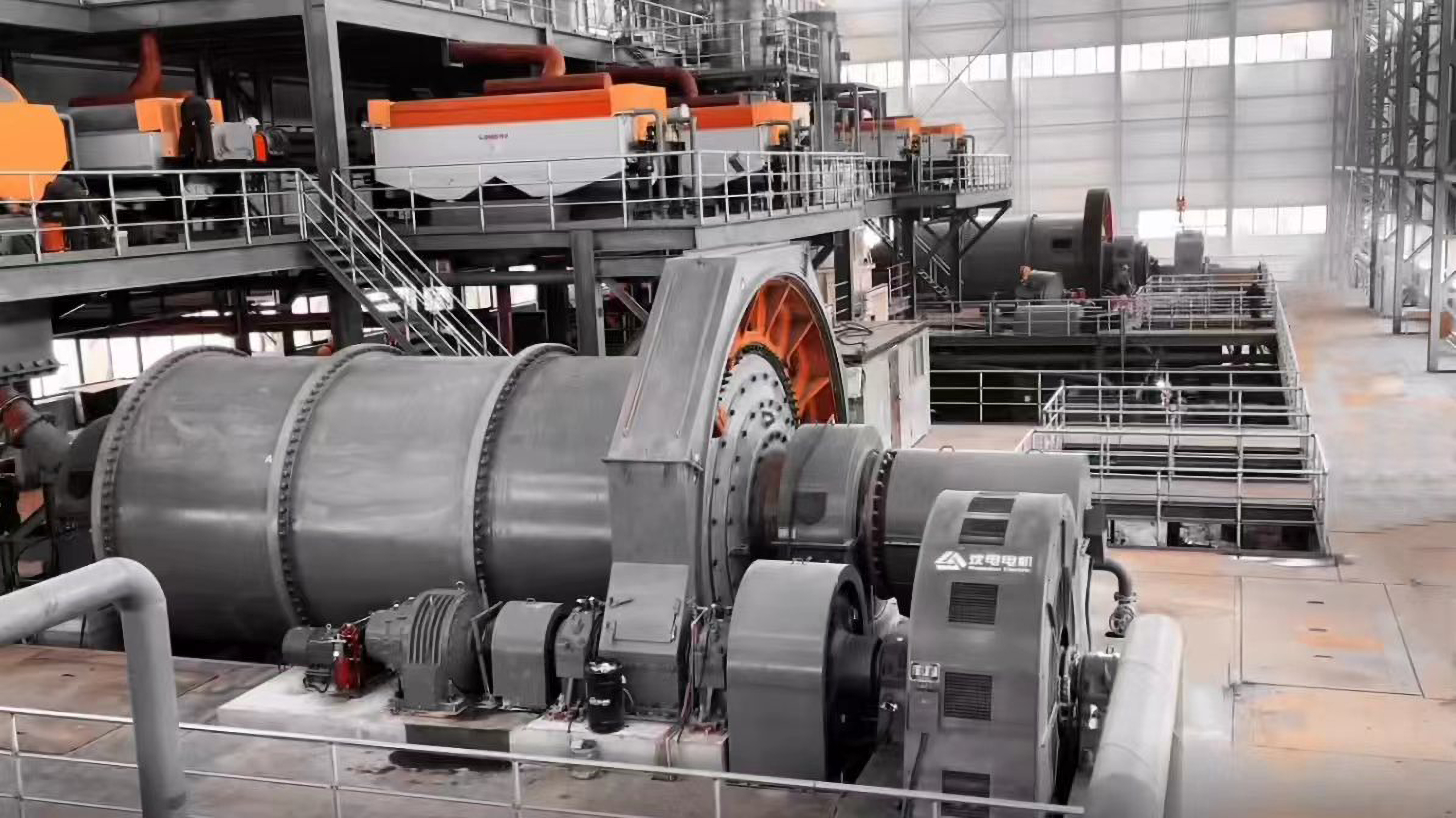

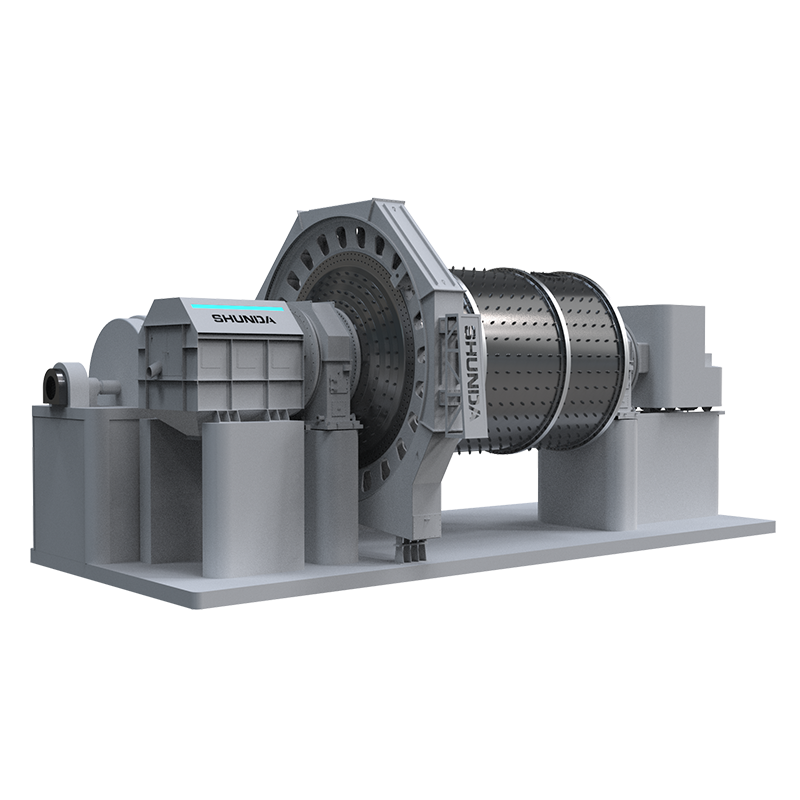

Ball mill is mainly used in power sector, non-ferrous metal ore separation, chemical industry, building materials and other industries.It is for grinding ore or other materials with bigger particle size into finer particle size.Since 2000,Shunda Group has been continuously innovating and developing to form a series of large ball mills of diameters from 2.1m to 6m,with independent IP rights.The working principle of ball mill is the same as that of SAG mill, which adopts overflow discharge mode. The feed size is usually less than 15mm to 20mm, and the final product particle size is from 200 mesh to 325 mesh.

The motor drives the shell filled with steel balls and materials to rotate through air clutch and gear set.The steel balls are lifted to a certain height and when the thrown and dropped movement occurs. The material is crushed by the impact of the steel balls and the grinding effect. Finally, the grinding process is completed by discharging from the mill with the water impulse.

With advanced, scientific and reasonable design, simple operation, convenient adjustment and maintenance, the ball mill can achieve reliable, stable, economical and efficient operation.It features with capacities of advanced overload protection, automatic monitoring and prediction of equipment failure.The built-in slag removal screen has the function of automatically removing large pieces of material and broken steel balls to protect the next section of equipment.The equipment adopts magnetic liner for second or third stage grinding. Its service life is several times longer than the ordinary manganese steel liner.

Characteristics of ball mill

Simple structure

High efficiency

Easy installation

Easy maintenance

The Wet Grate Discharge Ball Mill Performance Parameter List

| Model | Shell diameter(mm) | Effective length(mm) | Effective volume(m³) | Working speed(r/min) | Max.ball loading(t) | Motor power(kW) | |

| 1 | MQS2736 | 2700 | 3600 | 19 | 20.5 | 39 | 400 |

| 2 | MQS3245 | 3200 | 4500 | 33 | 18.4 | 65 | 800 |

| 3 | MQS3645 | 3600 | 4500 | 43 | 17.3 | 75 | 1250 |

| 4 | MQS3660 | 3600 | 6000 | 55 | 17.3 | 102 | 1600 |

| 5 | MQS4568 | 4500 | 6800 | 99 | 15.3 | 186 | 2600 |

| 6 | MQS4866 | 4800 | 6600 | 107 | 15 | 200 | 3000 |

Note: The above parameter table is for reference only. The actual production capacity depends on the material type and production conditions.

The Overflow Ball Mill Performance Parameter List

| Model | Shell diameter(mm) | Effective length(mm) | Effective volume(m³) | Working speed(r/min) | Max.ball loading(t) | Motor power(kW) | |

| 1 | MQY2745 | 2700 | 4500 | 23 | 20.5 | 43 | 450 |

| 2 | MQY3245 | 3200 | 4500 | 33 | 18.4 | 61 | 630 |

| 3 | MQY3260 | 3200 | 6000 | 43 | 18.4 | 75 | 1000 |

| 4 | MQY3660 | 3600 | 6000 | 55 | 17.2 | 102 | 1250 |

| 5 | MQY4060 | 4000 | 6000 | 67 | 16.8 | 115 | 1500 |

| 6 | MQY4080 | 4000 | 8000 | 92 | 16.8 | 153 | 2000 |

| 7 | MQY4564 | 4500 | 6400 | 94 | 15.3 | 157 | 2100 |

| 8 | MQY4575 | 4500 | 7500 | 109 | 15.3 | 183 | 2500 |

| 9 | MQY5083 | 5030 | 8300 | 151 | 14.4 | 257 | 3600 |

| 10 | MQY5585 | 5500 | 8500 | 185 | 13.7 | 300 | 4500 |

1.Ball mill's advantage is mainly in the use of magnetic lining, lighter weight.

2.Ball mill has a long service life.

3.Ball mill has less consumption and larger capacity.

Q: What is your company's business principle?

A: Our company regards quality as life and serving users as God.

Q: What is our warranty?

A: 100% brand new when leaving the factory, the seller guarantees the quality of the machine (excluding easy-to-wear parts) for one year from the date of completion of the trial run, but no more than 15 months from the date the machine leaves the factory.

Q: What is the price of this product?

A: We can give the lowest price than the market, and we will provide a quotation for any customer as soon as possible, and discounts can be given according to quantity.

Q: Service and payment terms?

A: We can accept T/T and L/C; 30% deposit, 70% balance paid before delivery, which is an international trade practice; finished product pictures will be provided to customers before delivery.

Note: The above parameter table is for reference only. The actual production capacity depends on the material type and production conditions.