- Home

- >

- Products

- >

- Grinding Equipment

- >

- Disc Mill

- >

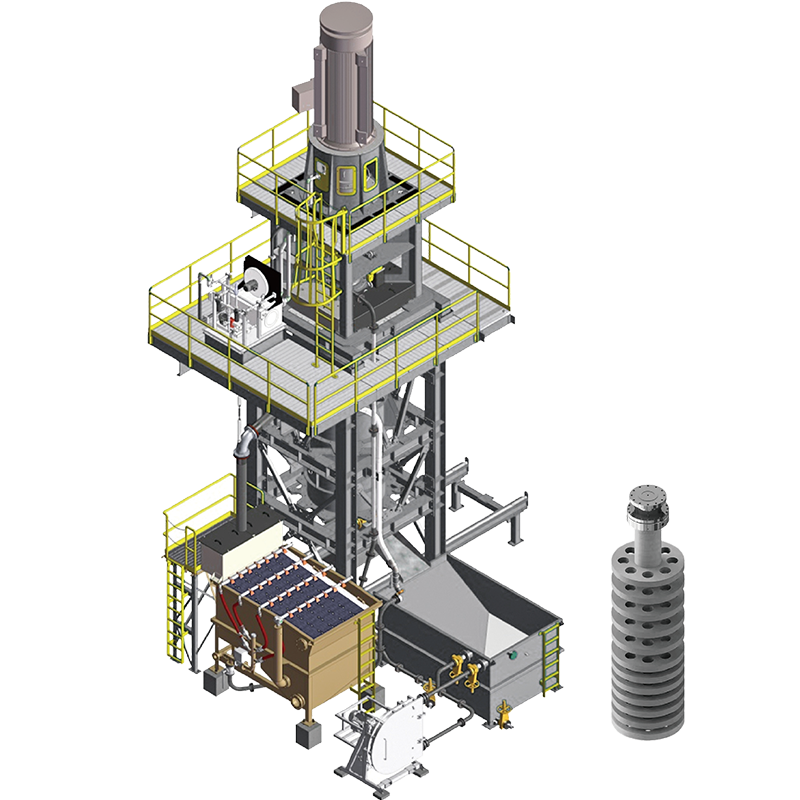

Introduction of Disc Mill

Among the medium steel balls and the medium balls with the disc are generated friction and shear force. Under the action of momentum and impulse, the ore material is deformed, fractured and finally crushed to the ideal particle size.

The maximum feeding grain size is 0.5 mm, and the minimum discharging grain size is 5um.

Advantages of Disc Mill

No rotary seals,no slurry leakage

High speed centrifugal stirring

Stable operation with low maintenance cost

Automatically refill grinding medium

The installation of disc mill is different from the horizontal installation of the ISA mill,the disc mill is vertically installed.Feeding materials from the bottom and discharge products by overflowing.Compared with the ISA mill,it occupies smaller space.Due to the characteristics of the overflow,there is no rotary seal,so that it is not possible for slurry leakage.The ore slurry does not contact with bearings,so the bearing wear less,where the mechanical structure is more stable;all these factors help with the lower maintenance cost.There is no metal surface in the grinding chamber, making it more suitable for ultra-fine grinding of precious metals and rare metals.

Technical features

1. Ceramic ball medium.

2. Automatically refill the grinding medium

3. High speed centrifugal stirring.

4. Feed materials from the bottom, overflow.

5. Product particle size: 20μm~5μm.

6. No rotary seal,no slurry leakage.

7. Vertical installation.

8. Stable operation with low mainte nance cost.

9. Suitable for precious metals and rare metals.

10、No metal in the grinding chamber.

Parameter Table of Disc Mill

| Model | Shell volume(L) | Main motor power(kW) | Capacity(tph) | |

| 1 | SDDM100 | 110 | 110 | 4-7 |

| 2 | SDDM250 | 290 | 132 | 6-12 |

| 3 | SDDM500 | 480 | 225 | 10-20 |

| 4 | SDDM1000 | 910 | 355 | 15-35 |

| 5 | SDDM2500 | 2425 | 700 | 30-70 |

| 6 | SDDM5000 | 5026 | 1500 | 80-180 |

Note: The above parameter table is for reference only. The actual production capacity depends on the material type and production conditions.

FAQ

Q: What is your company's business principle?

A: Our company regards quality as life and serving users as God.

Q: What is our warranty?

A: 100% brand new when leaving the factory, the seller guarantees the quality of the machine (excluding easy-to-wear parts) for one year from the date of completion of the trial run, but no more than 15 months from the date the machine leaves the factory.

Q: What is the price of this product?

A: We can give the lowest price than the market, and we will provide a quotation for any customer as soon as possible, and discounts can be given according to quantity.

Q: Service and payment terms?

A: We can accept T/T and L/C; 30% deposit, 70% balance paid before delivery, which is an international trade practice; finished product pictures will be provided to customers before delivery.