- Home

- >

- Products

- >

- Grinding Equipment

- >

- SAG Mill

- >

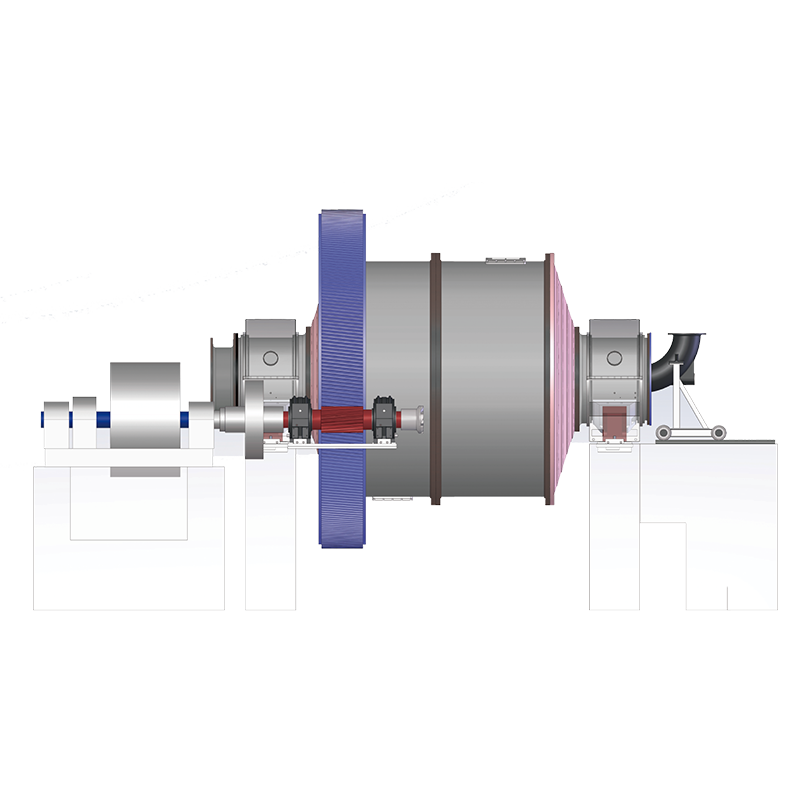

Advantages of SAG Mill

Simple structure

High efficiency

Easy installation

Easy maintenance

Working principle

The ore material after coarse crushing (particle size usually less than 300mm)is to be fed through the feeding chute into the mill cylinder body;The rotating cylinder is filled with a certain amount of steel balls and bulk ore of different specifications and proportions (the maximum filling rate of steel balls is ≤ 15%, and the total filling rate is generally ≤ 35%). The steel balls and ore are thrown and dropped in the cylinder (mainly the throwing movement)for the ore materials to be impacted and ground. The bulk ore materials are ground into finer ore less than 15mm and ready to supply to the next grinding equipment.

Process feature

In the SABC process, the continuous feeding of the SAG mill shell is accompanied by the continuous feeding of fixed amount of process water, then the mixed fluid is formed by ground fine materials and water. Under the action of the pressure difference of the mixed fluid, materials are selectively separated through the grid plate.

In the SABC process, the continuous feeding of the SAG mill shell is accompanied by the continuous feeding of fixed amount of process water, then the mixed fluid is formed by ground fine materials and water. Under the action of the pressure difference of the mixed fluid, materials are selectively separated through the grid plate.

SAG mill (rough grinding) has the following specifications

φ4m series, φ5m series, φ5.5m series, φ6m series, φ6.4m series, φ7.5m series, φ8 m series, φ8.8m series.

Parameter Table of Semi Autogenous Mill

| Model | Shell diameter(mm) | Effective length(mm) | Effective volume(m³) | Working speed(r/min) | Max.ball loading(t) | Motor power(kW) | |

| 1 | MZS4014 | 4000 | 1400 | 16 | 17 | 11 | 400 |

| 2 | MZS5518 | 5500 | 1800 | 39 | 13.7 | 34 | 800 |

| 3 | MZS6030 | 6000 | 3000 | 78 | 13.2 | 63 | 1300 |

| 4 | MZS6433 | 6400 | 3300 | 99 | 13.2 | 80 | 2000 |

| 5 | MZS8848 | 8800 | 4800 | 273 | 10.8 | 219 | 6500 |

Note: The above parameter table is for reference only. The actual production capacity depends on the material type and production conditions.

FAQ

Q: What is your company's business principle?

A: Our company regards quality as life and serving users as God.

Q: What is our warranty?

A: 100% brand new when leaving the factory, the seller guarantees the quality of the machine (excluding easy-to-wear parts) for one year from the date of completion of the trial run, but no more than 15 months from the date the machine leaves the factory.

Q: What is the price of this product?

A: We can give the lowest price than the market, and we will provide a quotation for any customer as soon as possible, and discounts can be given according to quantity.

Q: Service and payment terms?

A: We can accept T/T and L/C; 30% deposit, 70% balance paid before delivery, which is an international trade practice; finished product pictures will be provided to customers before delivery.